Hardness testing

Hardness generally describes the resistance that a material opposes to another, harder indenter. The material is elastically and plastically deformed by the compressive load with different indenters. The measured variable is the corresponding indentation depth or the permanent plastic deformation.

Universal Rockwell Hardness Tester ZwickRoell ZHR8150CLK

©

Nico Niemeyer

©

Nico Niemeyer

Manufacturer: LATZKE Härteprüfung GmbH

Short description: Universal Rockwell hardness tester with automatic load control equipped for plastics according to standard ISO 2039.

Test material: Plastics

Application: The method is applied for the determination of hardness for plastic and rubber with a 5 mm ball indenter according to standard ISO 2039.

| Technical Data | |

| Ball diameter | 5mm ball indenter |

| Load control | automatic |

| Specimen dimensions | 20 × 20 × 4 mm |

| Test area | 250 × 150 mm |

| Test standards |

|

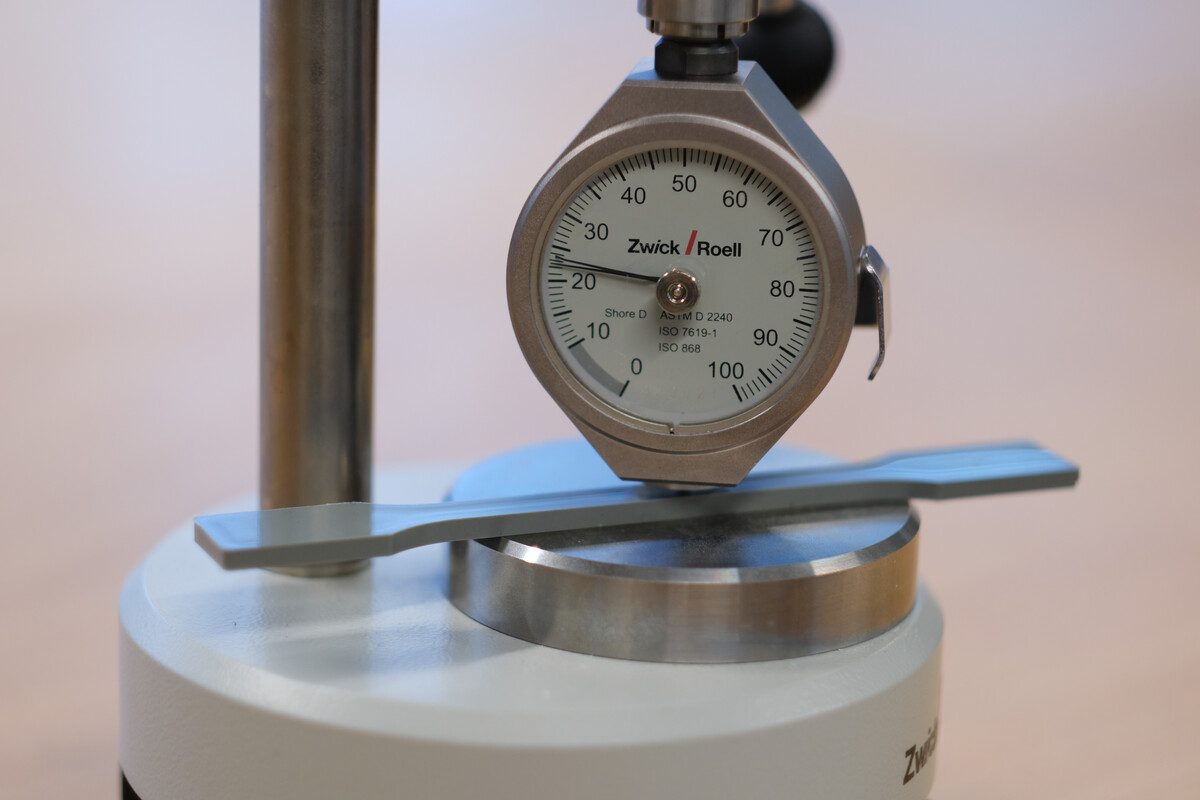

Shore hardness tester ZwickRoell 3115/16

Manufacturer: ZwickRoell GmbH & Co. KG

Short description: Analog Shore hardness tester with drag indicator for quick hardness testing of plastics. For Shore A hardness, the test body is a truncated cone and for Shore D hardness, a pointed needle. The measured variable is the resulting penetration depth at a given (spring) force.

Specimens according to Shore A: Soft rubber, elastomers and natural rubber (10 to 90)

Specimens according to Shore D: Harder elastomers and rigid thermoplastics (30 to 90)

Application: The method is used to determine the Shore hardness of plastics and elastomers as well as soft rubber. For the test procedure, the hardness tester is pressed against the sample with the required contact pressure until the contact surface is in firm contact. After firm contact of the contact surface with the sample, the hardness value can be read on the scale of the tester after 3 seconds (according to ISO) or 1 second (according to ASTM).

| Technical Data | |

| Test body | Shore A: Truncated cone ø = 0.79 ± 0.01 mm Shore D: Pointed needle R = 0.1 ± 0.01 mm |

| Contact pressure | Shore A = 12.5 N Shore D = 50 N |

| Specimen dimensions | Any, flat surface |

| Measured variable | 0 to 100 (dimensionless) |

| Test standards |

|