ReVor: Development of a pilot plant for plastics recycling

| Year: | 2024 |

| Funding: | European Regional Development Fund (ERDF) and State of Lower Saxony |

| Duration: | 09/2024 to 09/2028 |

There is currently no pilot plant that can be used to process complex plastic components or highly technical material composites in such a way that a high-quality recyclate can be produced from them.

The ReVor research infrastructure, funded by the European Union and the state of Lower Saxony, can close this gap and ensure that the development of processing strategies for optimised pre-treatment of the materials is made possible. This can take place in different process steps, which can be combined as required.

ReVor is based on the establishment of a semi-industrial plant technology centre as a real laboratory in which complex plastic components and material composites from technical applications are pre-treated so that they can be recycled. This includes, for example, plastic-metal composites from the shredder light fraction of end-of-life vehicles or electronic scrap from old electronic and electrical devices (E&E), composites such as glass fibre reinforced plastics (GRP), e.g. from rotor blades of wind turbines, various plastic waste from the construction sector such as window profiles, insulating materials, etc., for which there are currently no recycling solutions.

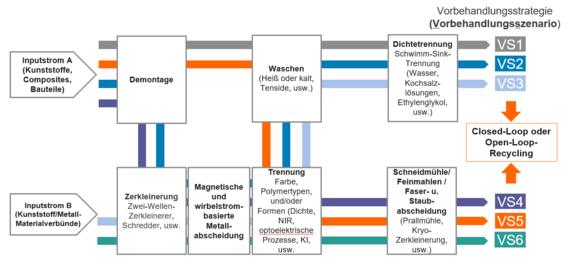

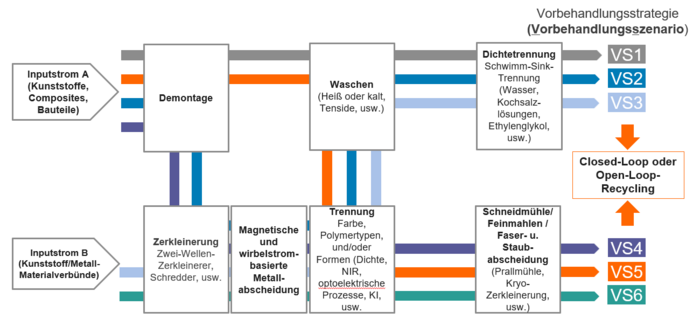

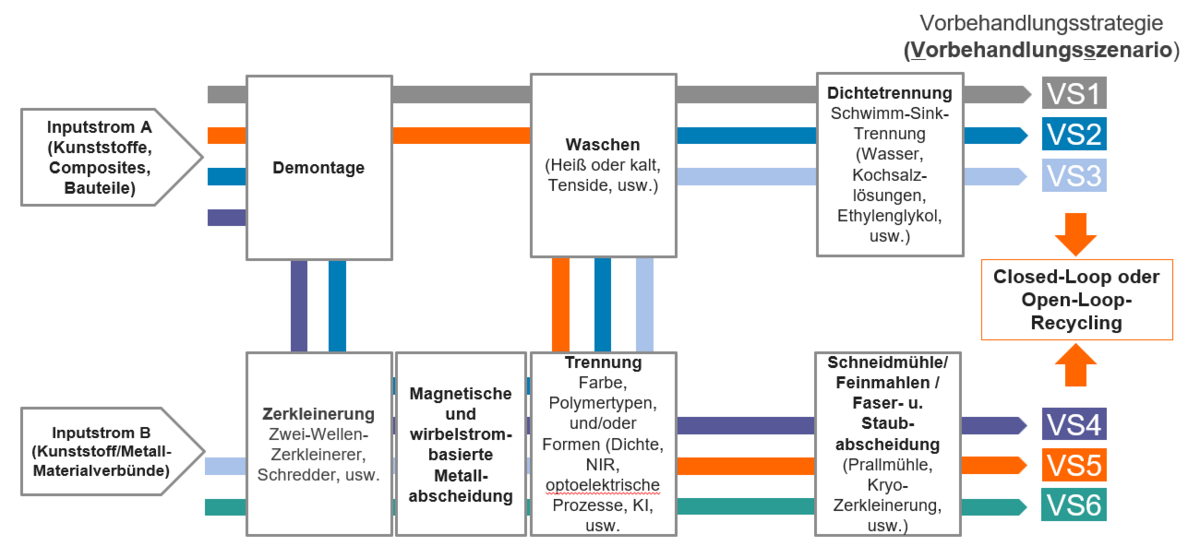

The proposed research infrastructure should consist of various specific, modular, semi-industrial process stages and plant components that can be flexibly connected in series and run through in any order, including cascading, see (Fig. 1).

©

IKK

©

IKK

If we want to produce high-quality post-consumer recyclates in the future, a multivariable and currently unique plant technology centre of this type is the basic prerequisite. From a recycling technology perspective, it enables the development of optimised pre-treatment strategies and process parameters for separating, cleaning and separating various components or materials and is unique in the research and industrial landscape.

The development of input-specific pre-treatment strategies for more complex components in recycling technology is the necessary ‘key factor’ for the recycling of previously non-recyclable technical components from the above-mentioned applications. This is the only way to fulfil the market demand for higher-quality post-consumer recyclates in the field of engineering plastics in the coming years, also in view of the stricter legal regulations.

For example, the effective separation of ferrous and non-ferrous metals from the shredder light fraction from the automotive sector or the E&E sector is heavily dependent on the size of the components and particles and leads to different results at different points in the pre-treatment process.

The various density separation processes must also be further developed in order to be able to separate technical plastics in a targeted manner. Spectroscopic separation processes with different mechanisms of action for separating the plastic fractions are further important process steps that are used at different points in the treatment process or are sometimes run through several times.The process parameters themselves include, for example, the speed, the material throughput of the shredding units during shredding, the temperatures used, the surfactants during washing, the wetting behaviour of the separation medium and the separation medium itself or the resulting dense cuts during float-sink separation or the particle size and sensitivity in the various spectroscopic separation processes, etc.

In addition to the flexibility of the modularly interconnectable process stages, the semi-industrial scale for input-specific pre-treatment is a key unique selling point of the project's plant technology centre.

For new input streams, it is currently only possible to utilise existing industrial treatment and recycling plants. However, the development of treatment processes for new input streams often fails due to the required quantities of input streams, the contamination of the plants with preliminary products, the lack of flexibility of the processes with regard to the process steps and process parameters and the lack of options for assessing the quality of the output of the respective intermediate stages.

Contact person

Madina Shamsuyeva

shamsuyeva@ikk.uni-hannover.de

+49 511 762 18345